RESOURCE EFFICIENT PRODUCTS FROM THE FOREST

We are proud to offer a sustainable product that enables green construction.

Wood Tubes’ EPD shows very little emissions during manufacturing, and over the entire life cycle, the studs capture -0,9 kg CO2e/meter.

At end of life, the Wood Tube stud is 100% recyclable.

01. Forest

Wood Tube studs are created with material from the forest and everything starts with wooden fibers growing strong inside of a tree. We believe in the forest as a source of renewable materials.

02. WASTE FROM THE FOREST INDUSTRY

When manufacturing paper, material from various waste streams can be utilized. For example, wooden chips from sawmills. These relations contribute to a circular economy and a resource efficient forest industry.

03. Paper

New trees and waste material go to a mill to become paper pulp. The paper pulp then goes to a paper mill where it becomes paper and can later be used in products such as paper packaging. When those products have been used they go to the paper recycling.

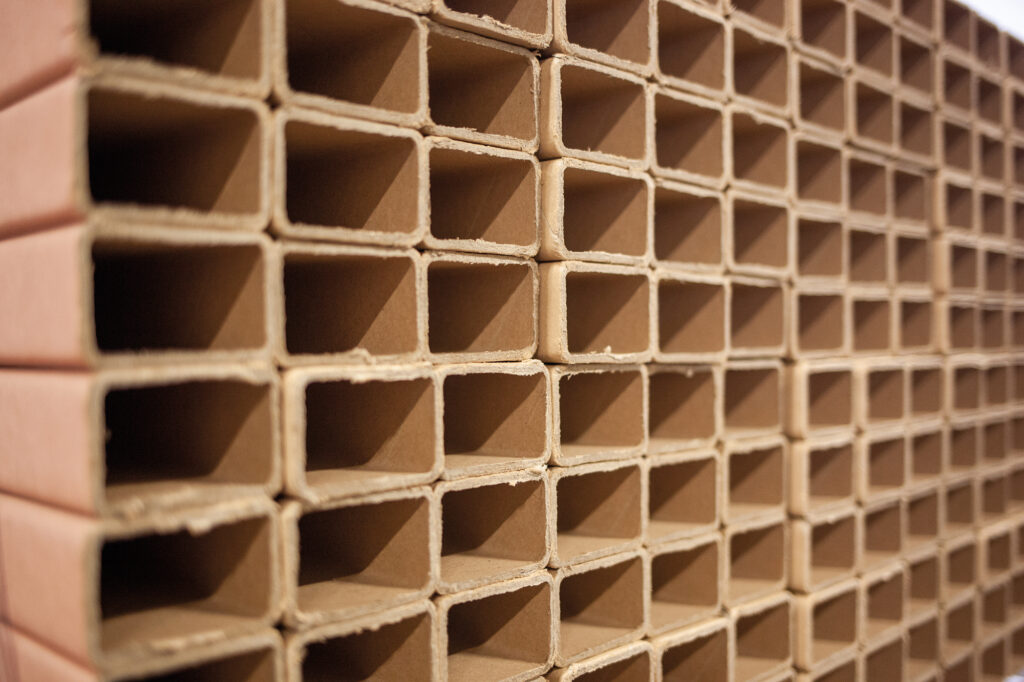

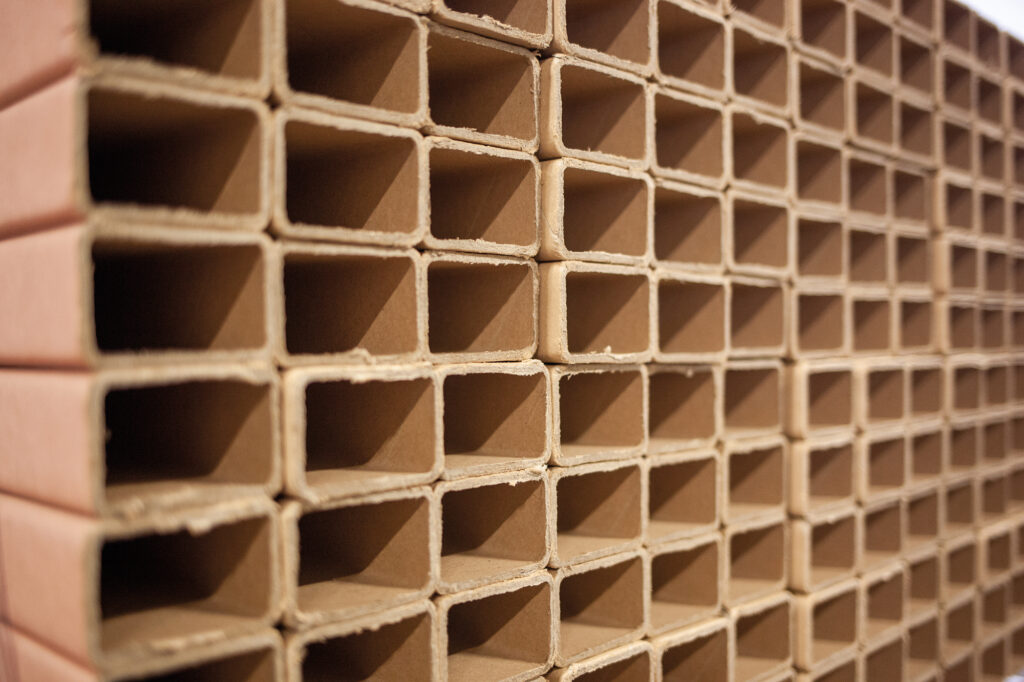

04. WOOD TUBE studs

When the used packaging has been recycled to become paper once again, the recycled paper goes to the Wood Tube factory in Säffle, Sweden. Together with glue we can go on to make the Wood Tube studs. The glue has been carefully chosen and only contain

ingredients that occur naturally. With the Wood Tube studs we can build the buildings of the future in a way that use natural resources in a responsible way. At end of life, the Wood Tube stud can be recycled and become new studs once again.

”Choosing Wood Tube’s climate-smart studs is making a choice for future generations”

UN Sustainable Development Goals

We are working with the following three goals from the UN Sustainable Development Goals. By working with us you are also part of the solution.

This goal is about promoting a safe and secure working environment for all workers, which we contribute to by improving the carpenters’ working environment.

We contribute to a sustainable industry by lowering CO2 emissions and using forest raw materials more efficiently.

We want to create access to sustainable, safe and affordable housing for everyone.